News Center

Function introduction of tool detector

Function introduction of tool detector

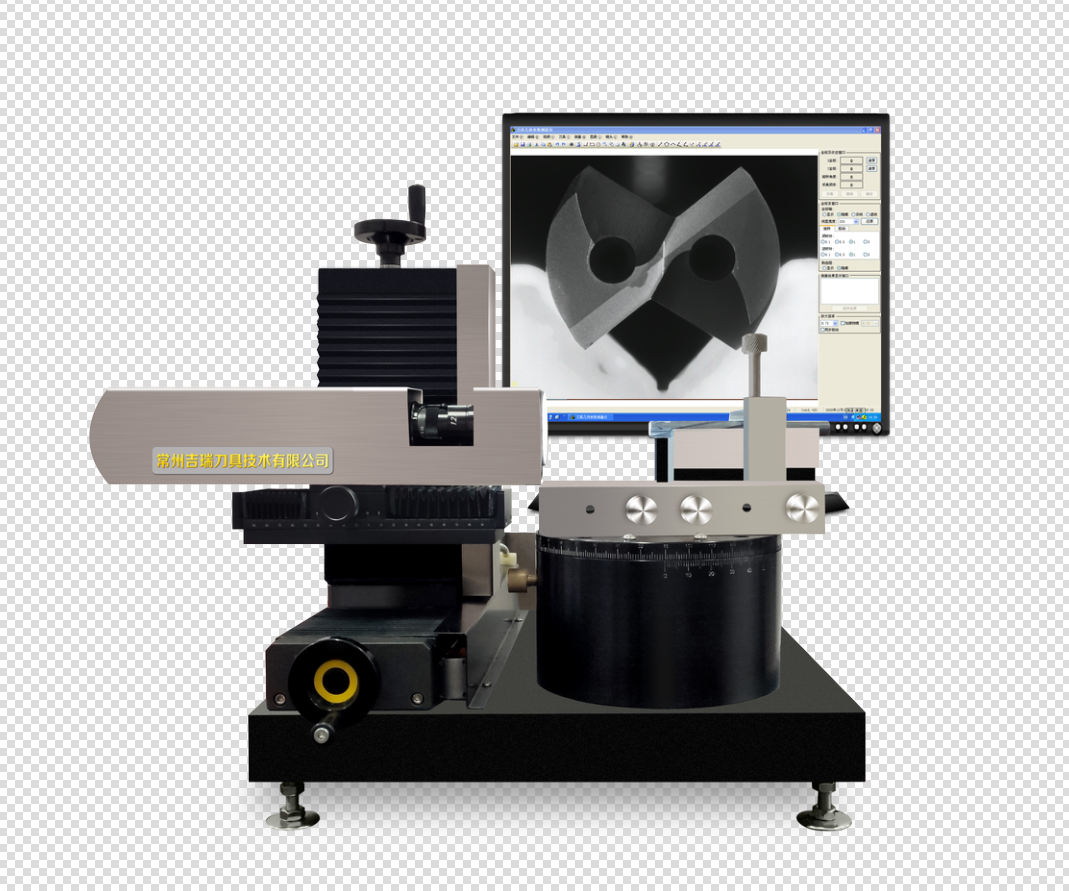

It is an optical CNC measuring machine to meet the requirements of non-contact tool measurement. Full-automatic precision measuring tools, with high measurement accuracy, can be used for precise measurement of geometric parameters and structural parameters of cylindrical milling cutters, conical milling cutters, drill bits, forming tools and grinding wheels, and can measure the geometric parameters/structural parameters of the tool such as the radius of the cutting edge, front angle, back angle, spiral angle, radial angle, axial angle, chamfer width, groove depth, symmetry, indexing, tooth pitch distribution, etc.

Main technical parameters

1. Mechanical part: 1) X axis: 270mm Y axis: 455mm Z axis: 325mm A axis: 360 °; 2) Maximum rotation speed: 60rpm; 3) Total resolution of measuring system: 0.25 μ m ; 4) Linear axis resolution:<0.02 μ m ; 5) Rotation axis resolution: ≈ 1“

2. Workpiece size: 1) Maximum workpiece diameter: 320mm 2) Maximum workpiece length: 420mm 3) Maximum workpiece weight: 25kg

3. Sensor technology: 1) 50 × Telecentric lens CCD 2) 100 × Horizontal direction CCD 3) 100 × Vertical direction CCD 4) automatic focusing

4. Measurement range: 1) 50 × External diameter directly measured by CCD: 100mm External diameter measured from the tool center: 320mm External contour (bilateral scanning): 320mm External contour (unilateral scanning): 100mm Circumferential back corner/chamfer width: 320mm Tool length: 420mm 2) 100 × CCD circumferential back corner/chamfer width: 320mm Slotted part: 100mm End face focal length Measurement depth: 60mm

5. Measurement accuracy: 1) Length measurement (room temperature 20 ℃) E1=(1.8+L/300) μ M Where: L=0 – 420mm 2) Diameter measurement (room temperature 20 ℃) E1=(1.8+L/300) μ M Where: L=0 – 100mm

6. Control system: 1) The integrated computer-aided control system can control the PLC through the network 2) Four action controllers highly integrated with power supply (60V/5A), I/O and interpolator 3) Windows 7 flagship 64-bit operating system (English version) 4) Industrial PC

7. Measurement software: 1) Walter Window Mode (WWM) 2) Teach mode (TIM) 3) Quick measurement module (QCM) 4) Easy check software package 5) Remote service software.

Application field

It can be used to quickly and accurately measure the geometric parameters and structural parameters of the tool, study the influence of the cutting edge form and structural parameters of the tool on the quality of the machined surface, and carry out the basic research on the high-quality creation of the surface physical properties based on cutting.

Related information

czhyly88@126.com

czhyly88@126.com

0519-8873 1215

0519-8873 1215

在线留言

在线留言